Pilot tests to achieve emission limit for DMF

In previous pilot tests, attempts were made to achieve the stricter emission limit for DMF of 2 mg/Nm³. Treatment by a regenerative thermal oxidizer (RTO) is then no longer sufficient. Therefore, the gas flow coming from the RTO must undergo a post-treatment. The pilot tests showed that there were different ways to achieve the emission limit, but that often too much wastewater was generated. That is why an ideal combination of efficiency and wastewater consumption was sought.

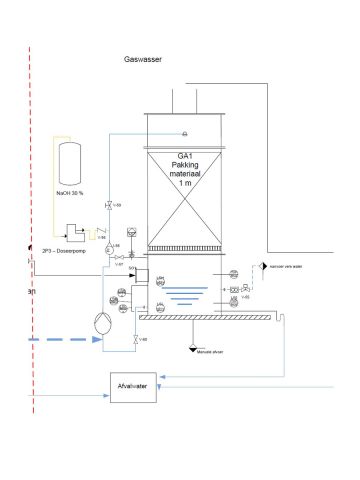

This time, the gas emission from the RTO was first cooled internally by passing through a cooling battery (using an ambiant air flow coolant blown by one/several fans), in order to achieve a much lower RTO exit temperature. This removes the need for cooling water. This cooled RTO gas stream was further cooled down by a water droplet sprayer system that also serves as a first gas scrubbing step. A water droplet separator scrubber was placed after this sprayer system. To remove the last residues of DMF, an active carbon filter is needed once the air flow was passed through a droplet separator. This droplet separator is necessary to reduce the humidity contained in the airflow, an airflow that is too humid is detrimental to the proper functioning of an activated carbon filter. This pilot test ensures an ideal combination of water consumption and activated carbon consumption. Activated carbon should be replaced after a while because it will become saturated with contaminants. With the use of a water droplet sprayer system and gas scrubber, there is already an initial reduction in DMF concentration in the RTO gas emissions. In order to optimize the water consumption of the scrubber and the sprayer system, the water from the scrubber is reused in the sprayer system, to reduce the overall water waste stream flow.

The ideal combination is now being studied. When the pilot tests are completed, we can offer the textile industry a tailor-made solution. This will include a spraying system, gas scrubber and activated carbon filter. Due to the combination of scrubber and active carbon filter, the emission limit of DMF can be achieved with a minimum in water consumption and active carbon consumption.

Are you also looking for help in carrying out pilot tests? Or are you struggling with an air purification problem? Be sure to give us a call!