RTO with bypass for pharmaceutical industry

Application

Our client is a global leader in the pharmaceutical industry. One of their factories, located in Spain, needed a RTO.

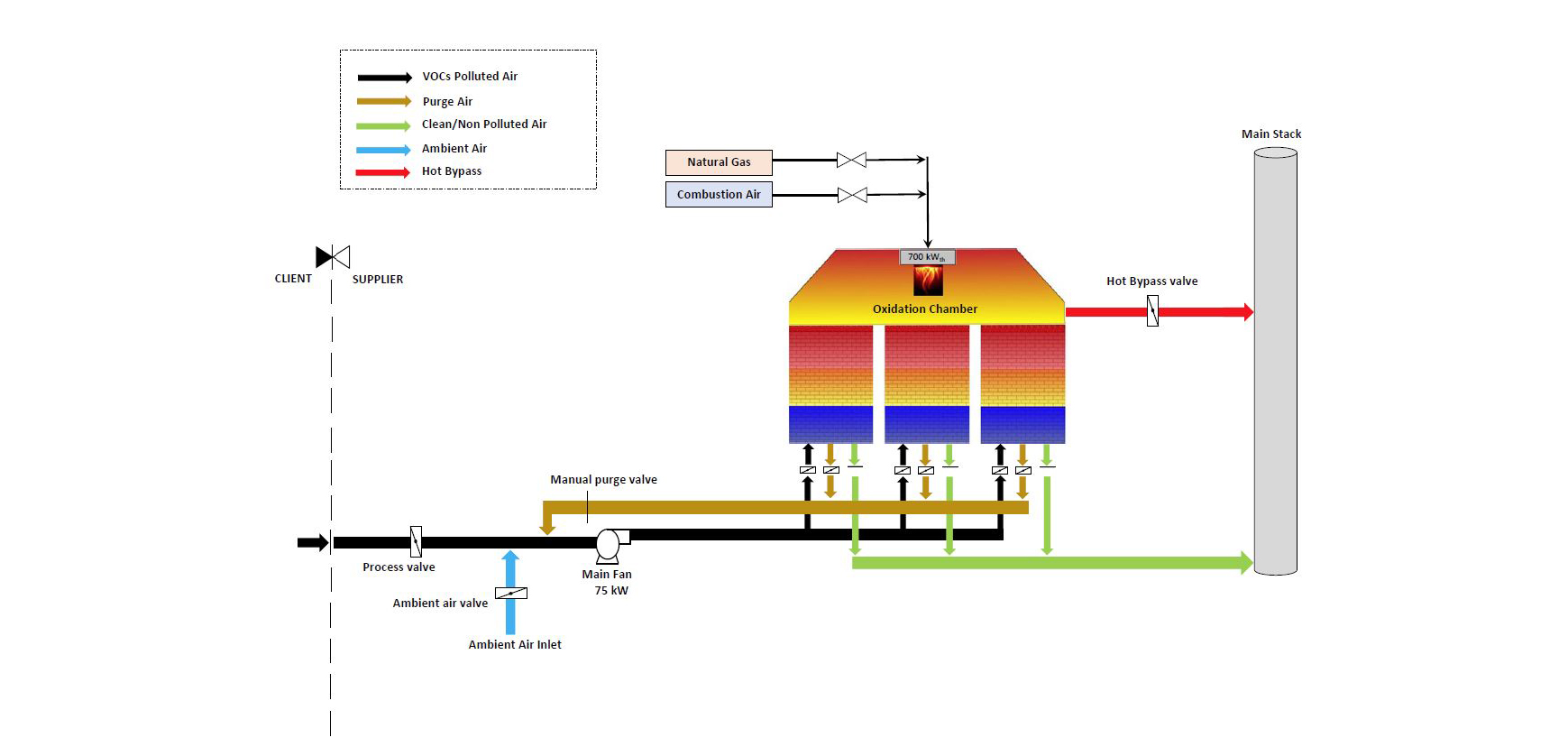

A lot of solvents (for example acetone, ethanol,…) are used during the production process of medication. The current European and Spanish environmental regulation prohibits the emission of such solvents in the atmosphere, so an air treatment with very high efficiency and certainty to treat such pollutants and concentrations was needed. Based on the composition of the air, the production process and the air flow it was advised that Regenerative Thermal Oxidation would be the most efficient solution in this specific situation.

The RTO oxidizes the polluted air stream at high temperature, which results in an air stream with almost no VOC’s. For safety reasons, it is crucial that the solvents concentration stays lower than 25% of the Lower Explosive Limit (LEL). For this reason the RTO was expanded with a clean airflow dilution and a hot bypass. When an excess of heat occurs, the valve of the hot bypass will open up automatically and release the excess of energy straight to the stack. Furthermore by diluting the air, the VOC concentration in the air flux can be kept below 25 % of the LEL.

Thanks to the safe and efficient installation and application of the RTO, our client can emit his air flow into the atmosphere without the slightest concern.

Specifications

| Flow rate | 24 000 Nm³/h |

| VOC concentration | 12,8 gr/Nm³ |

| Inlet temperature | 30 °C |

| Thermal efficiency | > 95 % |

| Heating capacity | 585 kW |

| Airflow low heating value | 30 MJ/kg |

Are you active in the pharmaceutical industry and having a similar problem? Or do you just have any question regarding air pollution control? Please contact our specialists!